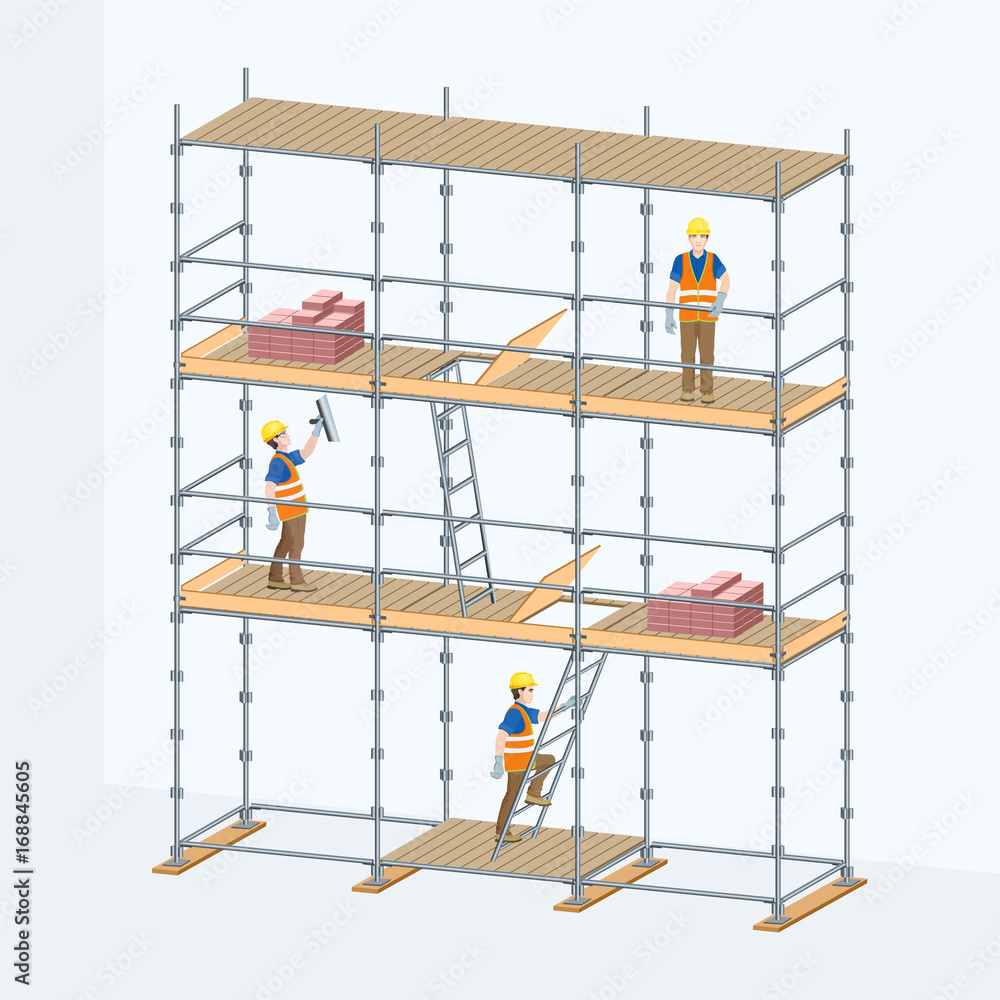

How to inspect a Scaffold. Scaffolding can refer to two different things:

- In construction, a scaffold is a temporary structure that is used to provide a safe working platform for workers who are doing repairs or construction at heights. Scaffolds are typically made of metal or wood and are supported by braces or ropes. They can be used to access high places, such as ceilings or roofs, or to provide a platform for working on walls or other vertical surfaces.

- In education, scaffolding is a teaching strategy that provides students with support as they learn new concepts or skills. The teacher gradually removes the support as the students become more proficient. This helps students to learn more effectively and to retain what they have learned.

Here are some examples of scaffolding in education:

- A teacher might provide a student with a graphic organizer to help them understand a new concept.

- A teacher might break down a complex task into smaller steps that the student can master one at a time.

- A teacher might provide a student with feedback on their work as they are doing it, rather than waiting until the end.

Scaffolding can be a very effective way to help students learn, but it is important to use it appropriately. The amount of scaffolding that a student needs will vary depending on their individual needs and abilities.

- Check the foundation and base of the scaffolding. Make sure that the foundation is level and that the baseplates are secure. The scaffold should also be the correct height for the work that is being done.

- Inspect the platforms. The platforms should be level and free of defects. There should be no gaps between the planks that are larger than 1 inch. The platforms should also be wide enough for the workers to safely access and work on.

- Inspect the bracing. The bracing should be secure and in good condition. The scaffold should be properly braced to prevent it from tipping over.

- Inspect the tubes and standards. The tubes and standards should be free of defects and should be properly connected.

- Check the load capacity. The scaffold should be able to support the weight of the workers, materials, and equipment that will be used on it.

- Check the access points. The access points to the scaffold should be safe and secure. There should be no gaps or holes that could cause workers to fall.

- Check for other hazards. Look for other hazards that could pose a safety risk, such as loose tools, tripping hazards, or exposed electrical wires.

Here is an example of a scaffolding inspection checklist that you can use:

Scaffold Inspection Checklist

- Foundation and base:

- Is the foundation level?

- Are the baseplates secure?

- Is the scaffold the correct height?

- Platforms:

- Are the platforms level?

- Are there any gaps between the planks?

- Are the platforms wide enough?

- Bracing:

- Is the bracing secure?

- Is the scaffolding properly braced?

- Tubes and standards:

- Are the tubes and standards free of defects?

- Are the tubes and standards properly connected?

- Load capacity:

- Can the scaffold support the weight of the workers, materials, and equipment?

- Access points:

- Are the access points safe and secure?

- Are there any gaps or holes that could cause workers to fall?

- Other hazards:

- Are there any other hazards that could pose a safety risk?

It is important to inspect scaffolds regularly to ensure that they are safe to use. Scaffold inspections should be conducted before each work shift and after any event that may have caused damage. If you find any defects or hazards during your inspection, you should take steps to correct them immediately.

There are many different types of scaffolding, but some of the most common include:

- Tube and coupler scaffolding: This is the most common type of scaffolding and is made up of metal tubes that are connected using couplers. It is a versatile type of scaffolding that can be used for a variety of tasks.

Tube and coupler scaffolding

- Trestle scaffolding: This type of scaffolding is made up of wooden trestles that are connected using braces. It is a simple and lightweight type of scaffolding that is often used for small projects.

Trestle scaffolding

- Cantilever scaffolding: This type of scaffolding is supported by a single vertical support and extends out from a wall or other structure. It is a good choice for projects where access to a specific area is needed.

Cantilever scaffolding

- Suspended scaffolding: This type of scaffolding is suspended from above using ropes or cables. It is a good choice for projects where access to the top of a building or other structure is needed.

Suspended scaffolding

- Bamboo scaffolding: This type of scaffolding is made up of bamboo poles that are tied together. It is a traditional type of scaffolding that is often used in Asia.

Bamboo scaffolding

The type of scaffolding that is best for a particular project will depend on the specific needs of the project. It is important to consult with a scaffolding professional to choose the right type of scaffolding for your project.

In addition to the types of scaffolding listed above, there are also a number of specialized types of scaffolding that are used for specific tasks. For example, there are scaffolding systems that are designed for use in demolition, painting, and window cleaning.

The safe working load (SWL) of a scaffold is the maximum weight that the scaffold can safely support. It is important to calculate the SWL of a scaffold before using it to ensure that it is safe for the workers and materials that will be using it.

The formula for calculating the SWL of a scaffold is:

SWL = DL + 4*LL

Where:

- SWL is safe working load

- DL is the dead load (kg)

- LL is the live load (kg)

The dead load is the weight of the scaffold itself, including the platforms, braces, and other components. The live load is the weight of the workers, materials, and equipment that will be using the scaffold.

For example, if the dead load of a scaffold is 200 kg and the live load is 2000 kg, then the SWL of the scaffold would be 2200 kg.

It is important to note that the SWL of a scaffold may vary depending on the type of scaffold, the height of the scaffold, and the location of the scaffold. It is always best to consult with a scaffolding professional to determine the SWL of a particular scaffold.

Here are some additional tips for calculating the SWL of a scaffold:

- Always use the manufacturer’s specifications when calculating the SWL of a scaffold. The manufacturer’s specifications will take into account the specific design of the scaffold and the materials used to construct it.

- Be sure to include the weight of all of the components of the scaffold when calculating the dead load. This includes the platforms, braces, ladders, and other accessories.

- Estimate the weight of the workers, materials, and equipment that will be using the scaffold when calculating the live load. Be sure to include the weight of any tools or machinery that will be used on the scaffold.

- If the scaffold will be used in a windy or wet environment, you may need to increase the SWL to account for the additional forces.